Vision Inspection Machine for Quality Control in India

It is impossible to compromise on accuracy, speed, and consistency in the fast-paced manufacturing world of today. This is where Visimaster's Vision Inspection Machines come in handy. We use cutting-edge vision-based technology to detect, validate, and categorize flaws in real time, adding precision to your factory floor.

Our inspection methods guarantee that your output satisfies the highest quality standards, whether you're processing engineering sector in Vadodara, assembling electronics in Electronic City (Bengaluru), or manufacturing fasteners in Mumbai. Additionally, we assist with operations in Ludhiana and Bhiwadi, where manufacturing and automotive industries are being simplified using vision-based assembly machines.

What is a Vision Inspection Machine?

A vision inspection machine checks parts for flaws like scratches, dimensional problems, cracks, misalignment, and color irregularities using high-speed cameras, lighting systems, and sophisticated software algorithms. Consistent, impartial, and round-the-clock quality assurance is made possible by this automation. For defect detection and quality control, our solutions which include vision inspection equipment in Ahmedabad offer unparalleled dependability.

Why Vision-Based Inspection is Essential

- Improved Accuracy: Get rid of human mistakes and conduct incredibly precise inspections.

- Increased Productivity: Production cycles are accelerated by faster inspection.

- Zero Defect Strategy: Quick errors detection made possible for flawless output via real-time feedback.

- Data-Driven Decisions: Use detailed inspection analytics to enhance the inspection procedures.

Visimaster provides specialized solutions to meet a range of industrial needs, from vision system companies in Jamnagar to high-precision installations for vision system automation in Kolhapur.

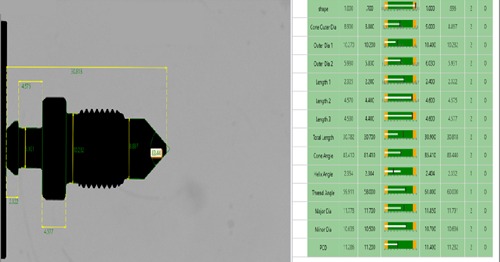

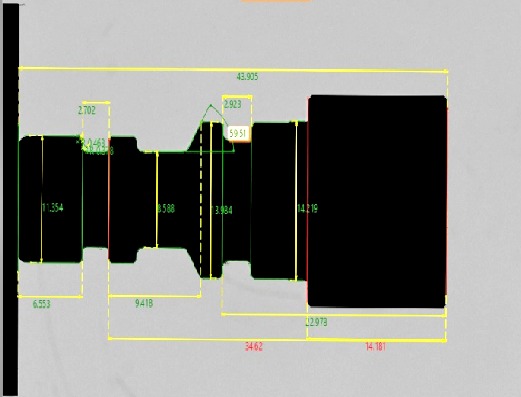

Dimensional Measurement Through Vision

Dimensional Measurement Through Vision

Applications Across Industries

Our vision systems are adaptable for a variety of industries:

- Automotive: Gear, bolt, and bearing inspections

- Packaging: Packing & sealing of products, barcode validation

Our machines are a perfect fit for every manufacturing setup, whether you're in Surat, Silvassa, Delhi, Chennai, or even industrial cities like Ludhiana, Jamnagar, Kolhapur, Bhiwandi, and Ahmedabad.

Stop Quality Escapes. Start Scaling with Precision.

The Vision Inspection Machines from Visimaster are designed for Indian manufacturers who are uncompromising.

Why Do You Continue to Perform Manual Inspection?

Manual quality assurance is untrustworthy, slow, and overlooks important flaws. That is not only inefficient in the high-speed industrial world of today, but it is also costly.

Manual inspection is replaced by Visimaster's Vision Systems, which include vision-based sorting machine solutions in Ludhiana and Bhiwadi.

Real Problems We Solve

- ✅ Missed cracks, scratches, dents, damage or operation missing

- ✅ Quality escapes reaching customers

- ✅ Bottlenecks in inspection

- ✅ Rising rework & rejection rates

- ✅ Human Errors, Quality compromise, Customer dissatisfaction

- ✅ Dependency on inspection tools, Excess Workforce

- ✅ Auditor headaches during compliance checks

What You Get with Visimaster

- Zero-Defect Output – 100% of flawless components at high speed

- Plug-n-Play Setup – Integrates with your existing line

- Detailed Analytics – By saving of inspection data, including Batch-wise Reports and SPC (Statistical Process Control) reports.

- Support Across India – Onsite + remote support from our local teams

Trusted Across Industries

- Auto: Bearings, gears, precision parts inspection

- Manufacturing: nuts, bolts, washers, dowels, circlips, o rings measurement deviation and surface flaws

- Packaging: Batch wise counting, Barcode Integration

Already Operational in These Hubs

Our machine vision solutions are already changing manufacturing quality standards in India's major industrial hubs, including Maharashtra, Gujarat, North India, South India, and East and West regions, including Mumbai, Nashik, Kolhapur, Aurangabad, Rajkot, Ahmedabad, Jamnagar, Surat, Delhi NCR, Baddi, Ludhiana, Bhiwadi, Faridabad, Rohtak, Chennai, Bengaluru, Coimbatore, Hosur, Jamshedpur, and Silvassa.

Our presence guarantees dependable and scalable vision solutions where they are most required, from vision inspection machine in Ahmedabad to vision system automation in Kolhapur and customized vision-based assembly machines in Ludhiana and Bhiwadi.

Vision Inspection Machines by Visimaster: Customized for Precision and Reliability

Our Vision Inspection Machines at Visimaster are made to specifically fit the needs of every application. To ensure that the machine provides the most dependable performance, we start by carrying out thorough application research, inspection trials, and an in-depth feasibility analysis.

We carry out extensive testing with different lighting configurations to select the best vision camera because vision-based inspection is highly sensitive to lighting, guaranteeing consistently accurate and reliable results.

We provide a full solution that includes a fully integrated workstation, vision system, marking system, and complete traceability solutions if the outcomes meet your quality criteria.

Why India’s Best Manufacturers Choose Visimaster

- ⚙️ Custom Built: Made to fit your part, dimensions, speed, and flaws

- 🧠 Deep learning and optics combined: AI + Optics

- 💼 Zero-Touch Reports: automatically created Excel/PDF inspection data

- 🛠 Local Support: anywhere in India for installation, instruction, and troubleshooting

- 🧩 Compact Models: for saving of space

Want to Stop Guessing & Start Knowing?

- ✅ Slash defect rates

- ✅ Reduce manpower costs

- ✅ Impress your customers

- ✅ Scale without fear

📞 Schedule a free discovery call with our technical staff.

Let's explore how Vision can improve quality control on your shop floor, not only in theory.